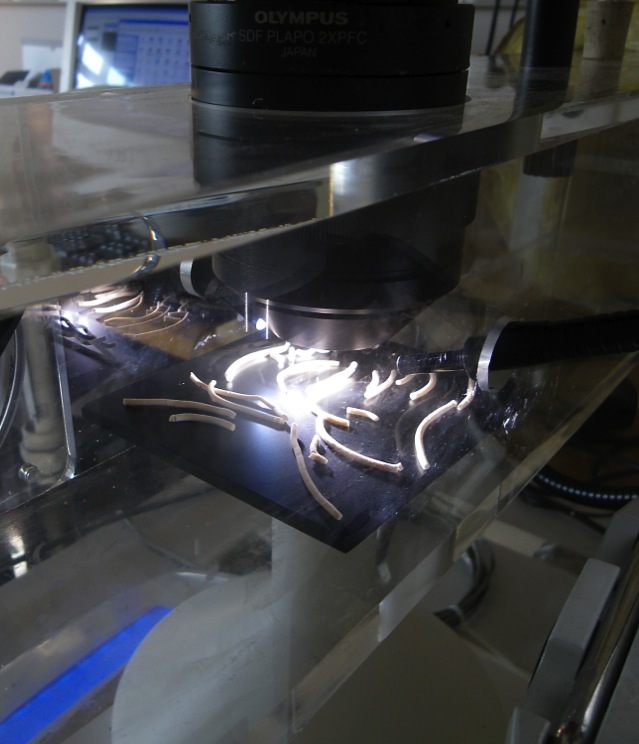

A contribution to a better understanding and modeling of the drying of a Baker's yeast rod-shaped pellet was achieved in this project. An original experimental setup was developed allowing the continuous characterization of the drying of a Baker's yeast pellet by using a precision balance, a microscope and an infrared camera. Using this experimental setup, the time evolution of the pellets moisture content, dimensions and surface temperature was obtained in a large set of operating conditions (air temperature, air velocity and initial pellet diameter). A new phenomenological model of the drying of a cylindrical Baker's yeast pellet was built on the basis of heat and mass transfer laws. It includes a description of the morphological change of the material during the drying and it provides a link between the initial drying rate and the Baker's yeast activity at the end of the drying. The unknown parameters were identified by a comparison with experimental results.

This set-up is was used to evaluate the impact of meteorologic condition (wind, temperature, air moisture content) on the kinetics of desaturation of soils. The desaturation of soil can lead to dramatic effect on road and infrastucture stability as the resistance of the soil might be falling drasticly when dried. Most models of desaturation of soils neglect the impact of surface effects, such as wind. The dyring tunnel allowed to have a precise analysis of the key transport phenomena. It was possible to express a critical humidity of the soil and to correlate it with the wind velocity. Above that critical humidity, the desaturation kinetics is controlled mailny by external effects while below the critical value, internal effects are the limiting phenomenon.