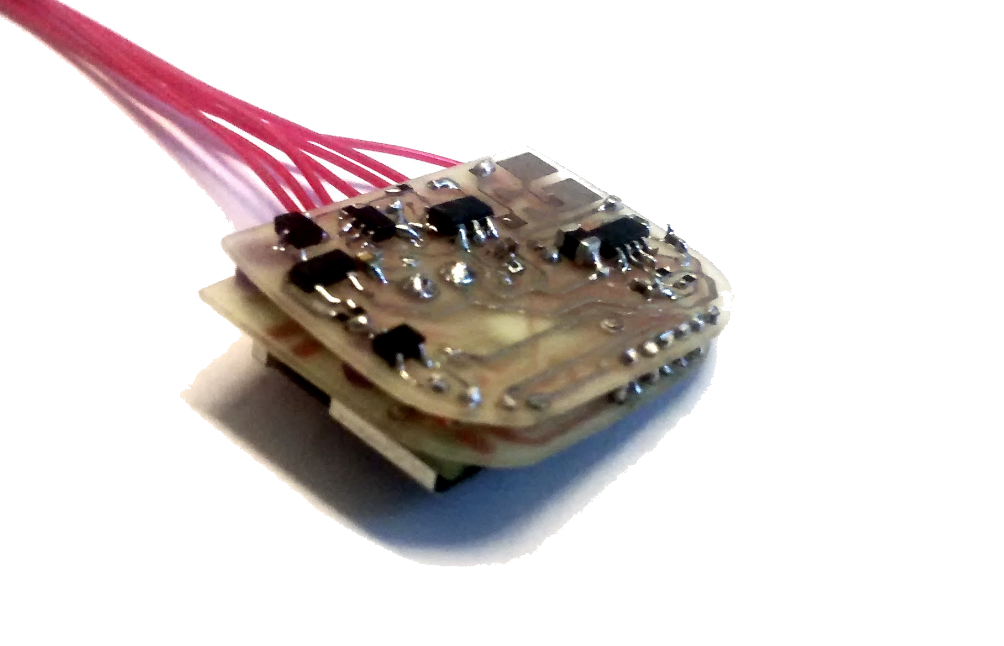

Example of electronics before encapsulation. It includes dynamically configurable stimulation stage, wireless powering and communication, chargeable battery, internal monitoring (e.g. charging and stimulation behaviour)…

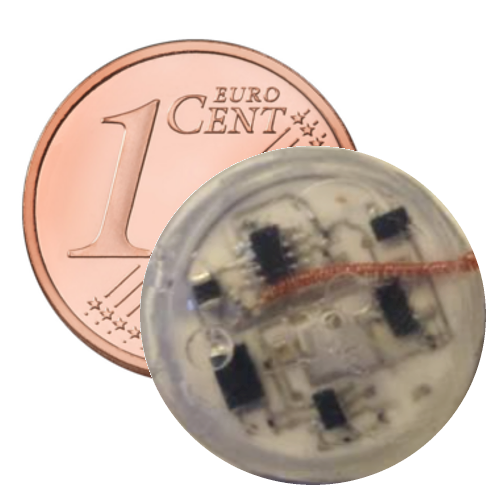

Example of active implant (17 mm diameter and 5.5 mm height). This gastrointestinal stimulator is intended to be anchored to the stomach through a full endoscopic procedure – hence with tight specifications on dimensions and weight. It aims to produce a feeling of satiety by stimulating the stomach.

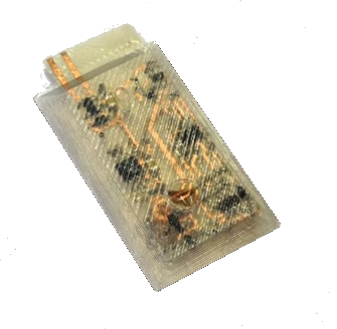

Example of flexible active implant. This implant is an example of soft encapsulation technique applied to flexible electronics. It opens the way to flexible implants that offer advantages over rigid devices.